Fakten

ISO or ANSI safety signs, or both?

2025-04-05

We will agree that safety instructions and the associated safety signs are highly relevant in technical communication. Nevertheless, it seems that in our increasingly complex environment, such fundamental aspects are undervalued when creating technical information and buzzwords such as AI, AR, VR, digital twin, etc. etc. dominate.

If anyone needs a little motivation to get involved with safety signs, here are a few figures on accidents at work in Germany. In 2019, there were 780,581 and in 2023 783,426 workplace accidents (DGVU), of which 615 and 599 respectively were fatal. Safety instructions with safety signs are not game changers, but they are a building block for improvement. Incidentally, the lever is, of course, inherently safe products, insofar as their function allows.

Hazard analysis and risk assessment are now reasonably well established, and as a result we have a basis that enables us to issue systematic and meaningful warnings about hazards, in particular with safety signs. Nevertheless, we are faced with a confusing array of safety signs, which has various causes. These include the arbitrary use of safety signs from symbol libraries, the established use of symbols in a specific company or industry environment, contradictory standards and the complex use for maximally inhomogeneous target groups. Specifically, the contradiction between ISO and ANSI safety signs repeatedly causes uncertainty. The recommendation to use safety signs according to ISO or ANSI depending on the location of the product is often difficult to follow. While this is possible for stationary industrial systems, manufacturers of assemblies, components and consumer products struggle with unclear target markets and target groups. Many such products are sold virtually without limit through web portals and resellers and, in the age of DIY, reach a highly motivated but not always highly competent target group. This is true even when it comes to assessing the risks of a product.

The ZVEI (ZVEI e. V. German Electrical and Electronic Manufacturers’ Association) has addressed this aspect of the dilemma facing its industry and is trying to counteract it. Two symbols are intended to alert buyers of products to the fact that electrical or mechanical expertise is required for installation.

ISO or ANSI safety signs?

Let’s stay on track and follow the “ISO-ANSI contradiction”. The casual term “ISO or ANSI safety sign” refers to safety signs from ISO 7010:2019-07 “Graphical symbols – Safety colours and safety signs – Registered safety signs” (and supplements) based on ISO 3864-3:2024-05 “Design principles for graphical symbols for use in safety signs” and safety signs based on ANSI Z535.3-2022 “Criteria for Safety Symbols”. The ISO standards are available in German, depending on the status of their adoption into the national standardization systems. This is a pair that we want to take a closer look at here.

ISO standards

First of all, let’s take a look at the binding nature of these standards. ISO standards represent the recognized rules of technology in the member states. The members are the standardization organizations of approximately 170 countries. That’s all the countries in the world, roughly speaking. The USA is also a member, represented by ANSI. The ISO standards are adopted in national or supranational (EU: 92/58/EEC) regulations and standards or legally effective reference is made to them. In Germany, this has been done with ASR A1.3 “Sicherheits- und Gesundheitsschutzkennzeichnung” (safety and health signs) of the “Technische Regel für Arbeitsstätten” (technical rule for workplaces). It is not possible to verify in practice how the discussed ISOs are implemented in the approximately 170 member countries. We have to assume that ISOs simply apply everywhere. The ISO provides us with ISO 3864, a design basis for standardized and individual safety signs, and ISO 7010, a catalog of safety signs. ISO 7010 has the often-highlighted flaw that a significant part of it has not been tested for comprehensibility or that not all comprehensibility criteria have been met.

ANSI standards

ANSI standards are also recognized rules of technology, only applicable in the USA in accordance with the country of the publisher. They are also applicable in Canada and Mexico through the United States-Mexico-Canada Agreement (USMCA) (formerly NAFTA). There is no general plan for implementing these into laws and regulations, but this has happened for the ANSI Z535 series in the regulations of the OSAH (Occupational Safety and Health Administration). OSAH is a US government agency with regulatory and enforcement authority over workplace safety, including safety labeling. ANSI also provides design guidelines for safety signs in ANSI Z535.3, but not a standardized collection of safety signs. Nevertheless, typical “ANSI safety signs” have become established in practice.

Sign manufacturers offer such “ANSI safety signs”, for example Clarion with a wide selection of standard-based safety signs, especially of so-called harmonized symbols (ANSI/ISO) and good information around the ANSI/ISO harmonization. This manufacturer is relevant because the founder and long-standing CEO Geoffrey Peckham chaired the ANSI Z535 committee for eight years.

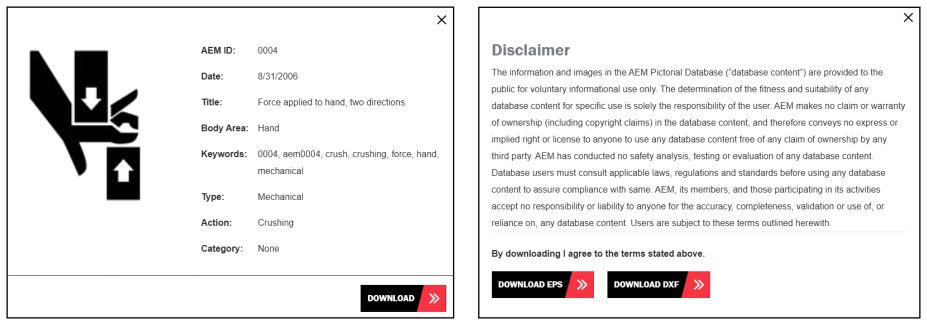

Or does the AEM (Association of Equipment Manufacturers) offer an image database with ready-made safety symbols for equipment manufacturers to download for free, if you want, a counterpart to ISO 7010. Counterpart? Not quite, because when the download is initiated, a note appears stating that the symbols have not been checked, have not been tested and that no liability is accepted. So we don’t find any tested safety signs in the ANSI world either. Even for the safety signs shown as examples in ANSI Z535.3, the standard states: “The symbols shown shall not be construed as approved, recognized, or in any way endorsed by the ANSI Z535 Committee.” The ANSI Z535 series refers to ISO standards in many places, both informatively and normatively. Over the last few versions, the ANSI Z535 committee has pushed ahead with a harmonization of ISO 3864. This is a necessary and timely step given the distribution channels described above.

As far as the binding nature of the ISO and ANSI standards for safety signs is concerned, the two worlds are very close and overlap. What about the design rules in detail? ANSI Z535.3 and ISO 3864-3 are nothing more than style guides for safety signs and are incredibly similar:

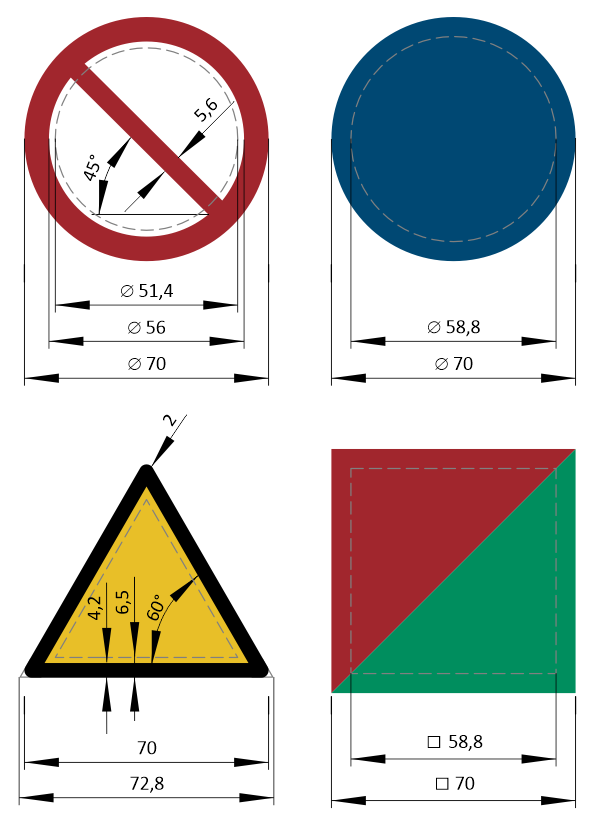

Basic figure

ISO 3864-3 (7.4) and

ISO 3864-1 (6)

Clearly defined basic figures for prohibition signs, mandatory action signs, warning signs, escape signs and fire protection signs with dimensions for the “symbol original”.

ANSI Z535.3 (5.1, A2, A3.2)

In principle, the basic figures are shown (2.75“ x 2.75” ≈ 70 x 70 mm), these are only mandatory for the safety alert symbol and the word mark. For all other basic figures, the loss of space for the symbol content must be considered.

Safety colors

ISO 3864-4 (Annex E)

Informative names of RAL colors. There is no official conversion of RAL colors into color values for RGB and CMYK and, from a purely technical point of view, there cannot be in an uncalibrated environment. However, there are (unauthorized) publications for approximate values, for example, for the safety color red with RAL 3001 signal red:

CMYK 20, 100, 100, 10 and

RGB 155, 36, 35

ANSI Z535.1 (Annex C, Table C-2)

Informative color values for RGB and CMYK.

Accordingly, the color values for Safety Red

CMYK 2, 100, 85, 6 and

RGB 200, 16, 46.

Line width

ISO 3864-3 (7.5)

The line width is defined with a minimum of 1 mm (exception: 0.5 mm) in relation to the size of the base figure.

ANSI Z535.3 (A3.2)

Line width and spacing between objects is with min. 0.04” (≈ 1 mm) in relation to the base figure.

Uniformity

ISO 3864-3 (7.6 … 7.8)

Symbol elements should be reused. Determinants (graphic symbols that are used repeatedly within a series of graphic symbols) should be used. Known symbol elements should be systematically combined in new symbols.

ANSI Z535.3 (A3.1 … A3.4)

Effective safety symbols are achieved through consistency, legibility, comprehensibility and simplicity.

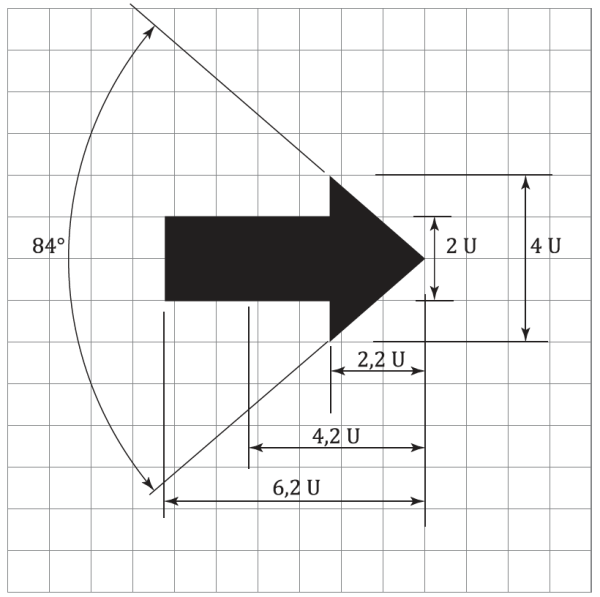

Arrows

ISO 3864-3 (7.9)

Definition of arrow shapes for motion, force and the movement of persons.

ANSI Z535.3 (A6.2)

Definition of arrow shapes for motion, force and the movement of persons in the informative appendix and reference to ISO 11684, which contains detailed information on arrow shapes.

Characters

ISO 3864-3 (7.10)

Letters, numbers, punctuation marks and mathematical symbols should not be used, with the exception of the exclamation mark.

ANSI Z535.3

No information.

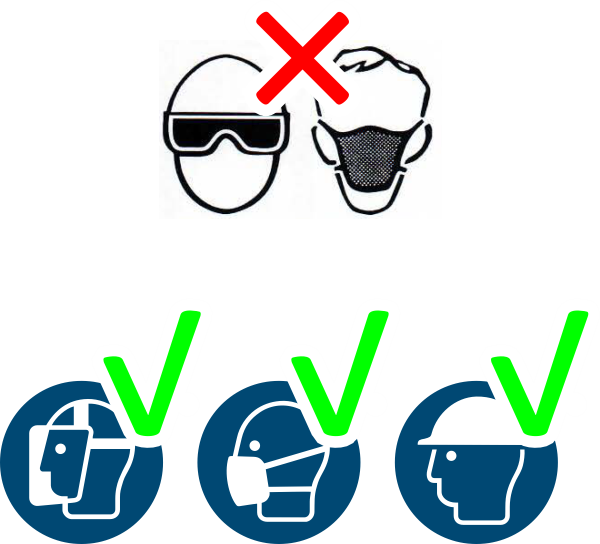

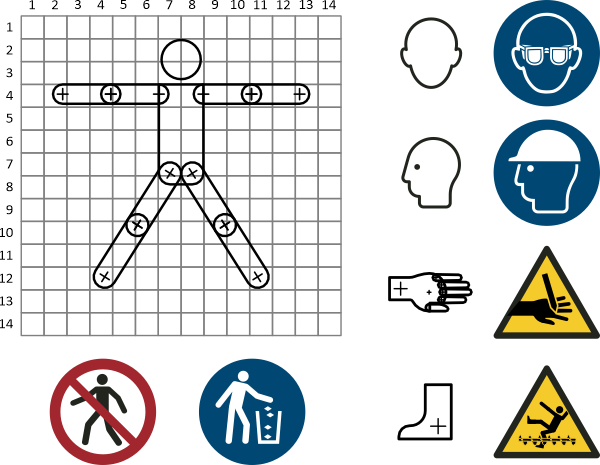

People and body parts

ISO 3864-3 (A.3)

Definition of people and body parts. People and body parts should be shown as an outline in safety signs for personal protective equipment and as a surface in safety signs for actions. The type of injury caused by the hazard should be shown, but not blood.

ANSI Z535.3 (A6.3, A6.3.5)

Definition of people and body parts. The hazard with impact and pain should be shown. Passive hands near a hazard are not sufficient and could convey the message “Put your hand here”. The representation of blood should be avoided.

Water

ISO 3864-3 (A.4)

If the symbol message is underwater, this is indicated by a wavy line, symbol messages above water by two wavy lines and deep water by several wavy lines.

ANSI Z535.3

No information.

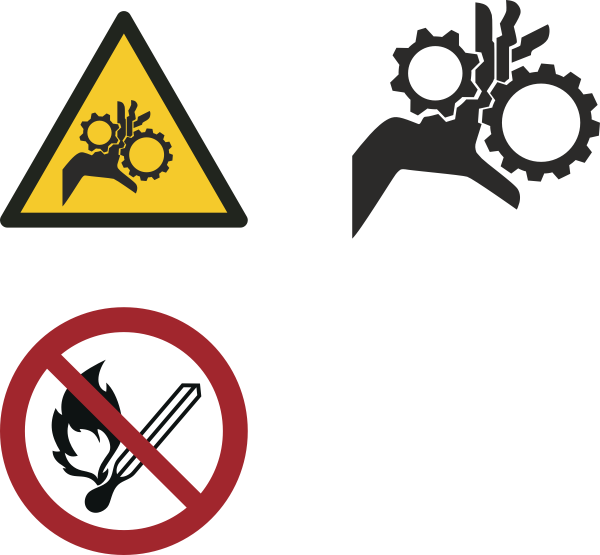

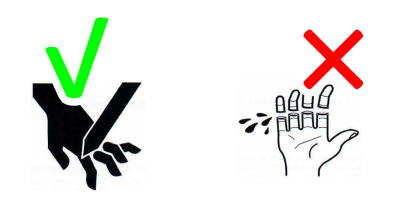

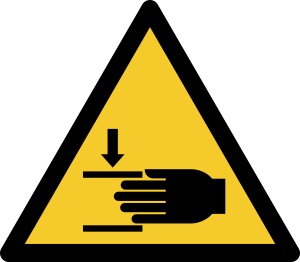

If you look at the design guidelines according to ISO and ANSI, you wonder how a safety sign like ISO 7010-W024 “Warning of hand injuries” and similar signs came about. Where is the illustration of the injury? It is only from the context of the yellow warning triangle that a danger can be inferred. This may be OK according to ISO, but the warning triangle is not obligatory according to ANSI. The fact is that a specific hand injury is also shown in compliance with ISO and ANSI.

ISO 7010-W024, based on ISO 3864-3

not standardized, but based on ISO 3864-3 and ANSI Z535.3

We are surrounded by abstract symbols that work well and that we have learned. Just think of the on/off symbol or the icon for saving… a floppy disk, even in the ubiquitous Microsoft 365, even though Microsoft loves the cloud so much. This disk icon seems to be a powerful convention, as bad as the icon is (now), because everyone after Generation Y (born from 1981 to 1995) lacks the representation of a disk. Personal sensitivities, evolved perceptions and their distortions are not good advisors when it comes to assessing the comprehensibility of safety signs. This is especially true in view of the worldwide use of products across different cultures, levels of education and areas of application. Even a supposedly poorly designed safety sign can work well if used systematically.

In a nutshell

Yes, standardized safety signs have problems with comprehensibility and are therefore subject to strong criticism. The standardization commissions themselves are partly responsible for this, routinely publishing safety signs in ISO 7010 that have not been tested, do not meet all test criteria and do not fully follow the self-imposed design guidelines. Accordingly, an additional text is recommended, unless the safety sign is explained by means of instructions, training or instruction. A dilemma, we use safety signs to free ourselves from cultural and linguistic constraints. Since we cannot comprehensively test the safety signs for comprehensibility, we fall back on culture- and language-dependent means.

Comprehensibility tests according to ISO 9186-1 (Graphical symbols – Test methods – Method for testing comprehensibility) provide for the context to be named when testing a graphic. This is good, correct and necessary, because every type of communication has a context. If we use safety symbols in a concrete way, the context is present. If the ISO tests according to its own standards (ISO 9186), a context can often only be roughly outlined. If test results are available for individual safety signs in ISO 7010, these are put into perspective during actual use, where the context can hardly correspond exactly to that specified in the test. For us, this is often only visible in the standard with one word or a group of words (for ISO 7010-W024 “Warning of hand injuries”, this would be “Closing mechanical parts of a machine/equipment”. So let’s not be unnecessarily unsettled if there are no test results for safety signs in ISO 7010, but use these standardized safety signs, develop our own if absolutely necessary or use common ones that are perceived as “ANSI symbols”. If we use standardized safety signs consistently, this massively supports comprehensibility and recognizability through familiarity. Just think of the many symbols and icons that have permeated our everyday world, which we readily accept and understand. Why? Because they are used consistently, even with their weaknesses.